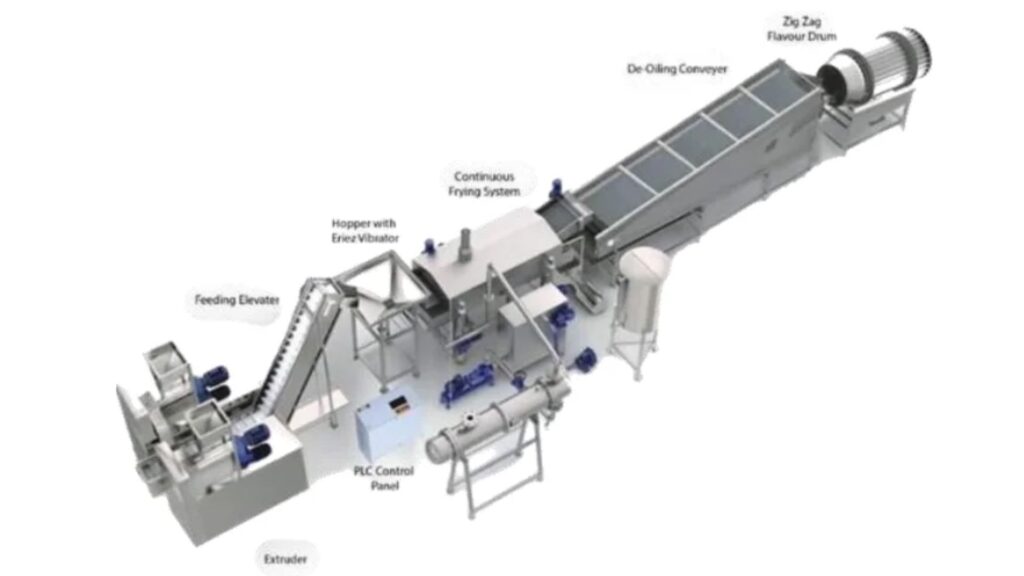

A Puffed Snacks Automatic Plant is an advanced, fully automated production system designed for manufacturing a variety of puffed snacks, including chips, puffs, and curls. The plant incorporates key processes such as raw material mixing, extrusion, shaping, drying or frying, flavoring, and packaging, all managed through a central PLC control system. It features a high-efficiency extrusion process, customizable molds for different snack shapes, and energy-efficient drying or frying systems. Built with food-grade stainless steel, the plant ensures hygiene, easy maintenance, and high productivity. Ideal for large-scale snack production, it delivers consistent quality, flexibility, and cost-effectiveness.

Puffed Snacks Processing Production Line Manufactures

Gulab Singh and Company isa a Leading puffed snacks processing production line Manufacturers & Suppliers in India. We are Provide Fully Automated Advanced puffed snacks processing production line to manufacture a wide range of puffed and extruded snacks such as corn puffs, cheese balls, rings, and curls. The line typically includes raw material feeding, mixing, extrusion, shaping, drying, flavoring, and packaging units. Using twin-screw or single-screw extruders, grains like corn, rice, or wheat are processed under high heat and pressure to create light, crispy textures. Interchangeable molds allow for a variety of snack shapes, while PLC touch-screen controls offer precise adjustment of processing parameters.

Snack Processing Production Line Manufactures

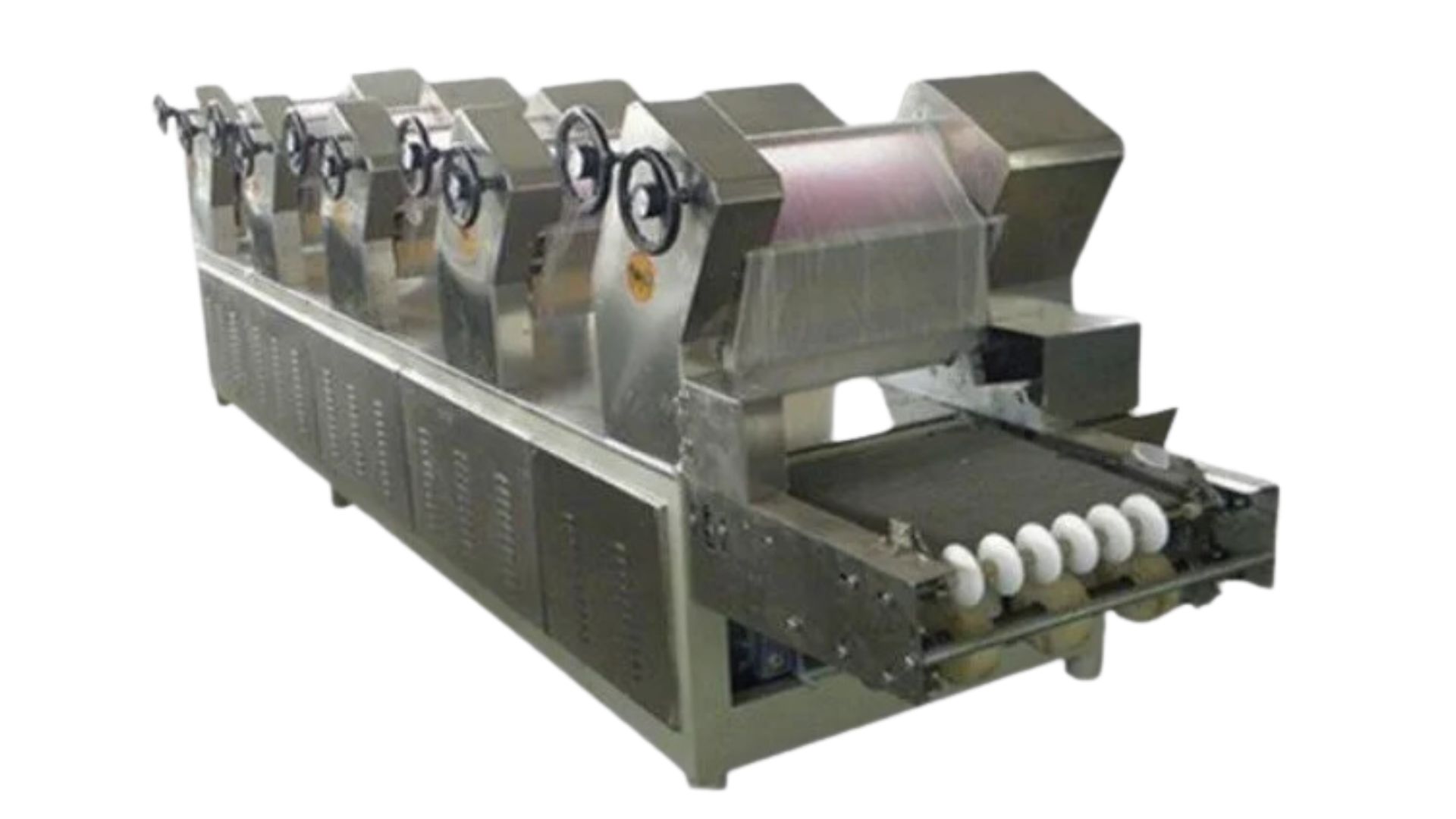

A Snack Processing Production Line is a fully automated system designed to produce a wide variety of snacks, including puffed, fried, or baked products. It features raw material mixing, extrusion or shaping, drying or frying, flavoring, and packaging. Key features include high-efficiency twin or single-screw extruders, PLC control with HMI interface, interchangeable molds for diverse shapes, energy-efficient drying or frying systems, and stainless steel construction for hygiene. The line supports continuous operation, quick changeovers, and consistent product quality. Ideal for scalable production, it meets the demands of modern snack manufacturing with flexibility, reliability, and reduced labor costs.

Maize Puff Extruder Machine Manufactures

The Maize Puff Extruder Machine is a specialized food processing unit designed to produce maize-based puffed snacks with various shapes and textures. It operates using a high-temperature, high-pressure extrusion process that transforms maize grits into light, crispy snacks. Equipped with a robust screw system, heating zones, and interchangeable dies, the machine ensures consistent shape and expansion. Its PLC control panel allows precise adjustments for temperature, speed, and pressure. Built from food-grade stainless steel, it offers durability, easy cleaning, and hygiene compliance. Ideal for both small-scale and industrial production, this machine delivers efficiency, product uniformity, and high output.

Puff Making Machines Manufactures

Puff Making Machines are specialized food processing equipment used to produce puffed snacks from raw materials like maize, rice, or wheat. These machines utilize high-temperature and high-pressure extrusion to create light, crispy snacks in various shapes such as balls, rings, and curls. Featuring advanced screw mechanisms, heating systems, and interchangeable molds, they ensure uniform expansion and texture. Most models include a PLC control system for precise operation and consistency. Made with food-grade stainless steel, they are durable, hygienic, and easy to clean. Puff making machines are ideal for snack manufacturers seeking high efficiency, scalability, and consistent product quality.

Snacks Puff Making Machine Manufactures

A Snacks Puff Making Machine is designed for producing a wide range of puffed snacks from grains like corn, rice, or wheat. Using high-pressure and high-temperature extrusion, the machine turns raw materials into light, crispy snacks with different shapes such as puffs, balls, or curls. The machine is equipped with a PLC control system for precise operation, ensuring consistent quality and texture. Made from food-grade stainless steel, it meets hygiene and safety standards, offering easy cleaning. Ideal for both small-scale and large-scale snack production, it ensures high output, energy efficiency, and flexibility in product variety.

Puffs Snacks Automatic Plant Manufactures

Maize Puff Making Machine Manufactures

The Maize Puff Making Machine is a specialized food processing equipment designed to produce puffed snacks from maize. It uses high-pressure and high-temperature extrusion to transform maize grits into light, crispy puffs with various shapes such as balls, rings, and curls. The machine is equipped with an advanced screw mechanism, precise temperature control, and interchangeable molds to ensure consistent quality and texture. It features a PLC control system for easy operation and monitoring. Built with food-grade stainless steel, it ensures hygiene and durability. Ideal for large-scale production, the maize puff making machine is efficient, versatile, and reliable for snack manufacturers.

Puffs Snacks Automatic Plant Manufactures

A Puffed Snacks Automatic Plant is a fully automated production line designed to manufacture a variety of puffed snacks, such as chips, puffs, and curls, from raw materials like corn, rice, or wheat. The plant integrates several key processes, including mixing, extrusion, shaping, frying or drying, seasoning, and packaging, all controlled by a central PLC system for precise operation. It features an efficient extrusion process, customizable molds for diverse shapes, and energy-saving drying or frying systems. Built with food-grade stainless steel, the plant ensures hygiene, durability, and easy maintenance. Perfect for large-scale snack production, it delivers consistent quality, high productivity, and flexibility.