Continuous Fryer Manufacturer

Gulab Singh and Company, based in Ghaziabad, Uttar Pradesh, is a leading manufacturer, supplier, and exporter of high-quality continuous fryer machine in India. Our advanced fryers cater to diverse industrial needs, ensuring efficient and uniform frying for snacks.

Continuous Fryer Machine Manufacturer

Our Products

Continuous Fryer Features

- Versatile Automation Options: Available in automatic, semi-automatic, and manual configurations to suit various production needs.

- High-Quality Construction: Made from mild steel or stainless steel, ensuring durability and compliance with food safety standards.

- Efficient Heating System: Designed for optimal frying performance with precise temperature control, enhancing product quality.

- Customizable Capacity: The fryer can be tailored to different production volumes, accommodating a range of snack foods.

- User-Friendly Operation: Engineered for easy handling and maintenance, making it accessible for operators in commercial settings.

| Specification | Details |

|---|---|

| Manufacturer | Gulab Singh and Co. |

| Product Name | Continuous Fryer |

| Type | Food Processing Machine |

| Material | Mild Steel or Stainless Steel |

| Automation Grade | Automatic, Semi-Automatic, Manual |

| Voltage | 220 V |

| Frequency | 50 Hz |

| Power Consumption | Varies based on model (specifics not provided) |

| Production Capacity | Customizable (specifics not provided) |

| Country of Origin | Made in India |

| Year Established | 2006 |

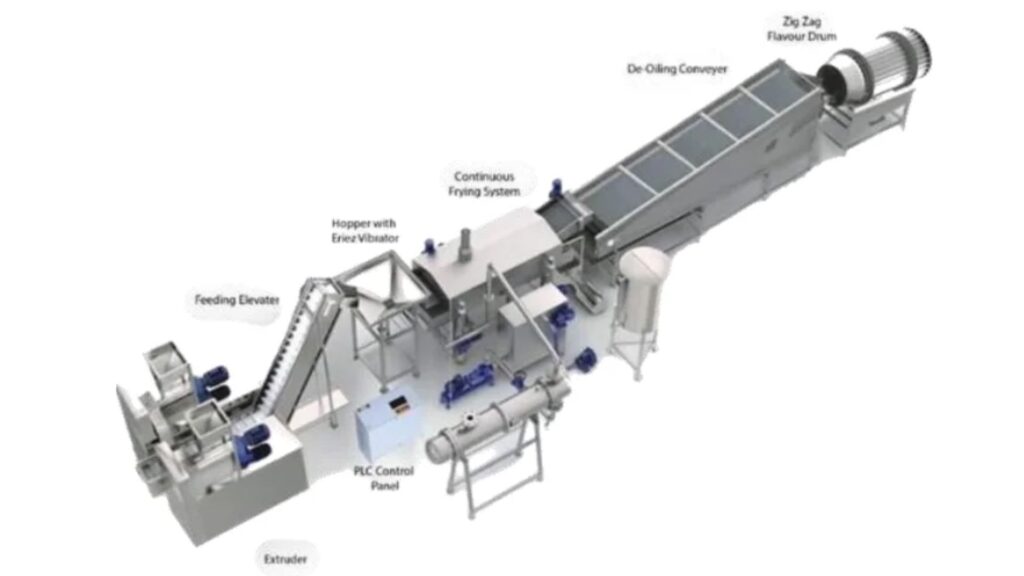

We specialize in automatic continuous fryers, including multi-product continuous frying systems and heavy-capacity automatic fryers, perfect for large-scale production. Whether you’re producing namkeen, bhujia, or potato chips, our fryers provide precise temperature control, consistent frying, and energy efficiency.

Our continuous snacks fryer machines are designed to handle high production demands. The continuous frying system ensures an uninterrupted process, making it ideal for large snack manufacturers. For versatility, our industrial continuous fryer accommodates different snack varieties, meeting the needs of a modern food processing unit.

We also provide options for used continuous fryers, offering cost-effective solutions without compromising quality. With our continuous potato chips fryer machines, we ensure optimal performance and durability.

Choose Gulab Singh and Company for premium continuous frying systems, trusted by industries across India and beyond. Contact us today for efficient, reliable, and high-capacity frying solutions!

How Continous Fryer Machine Work ?

What is a continuous fryer?

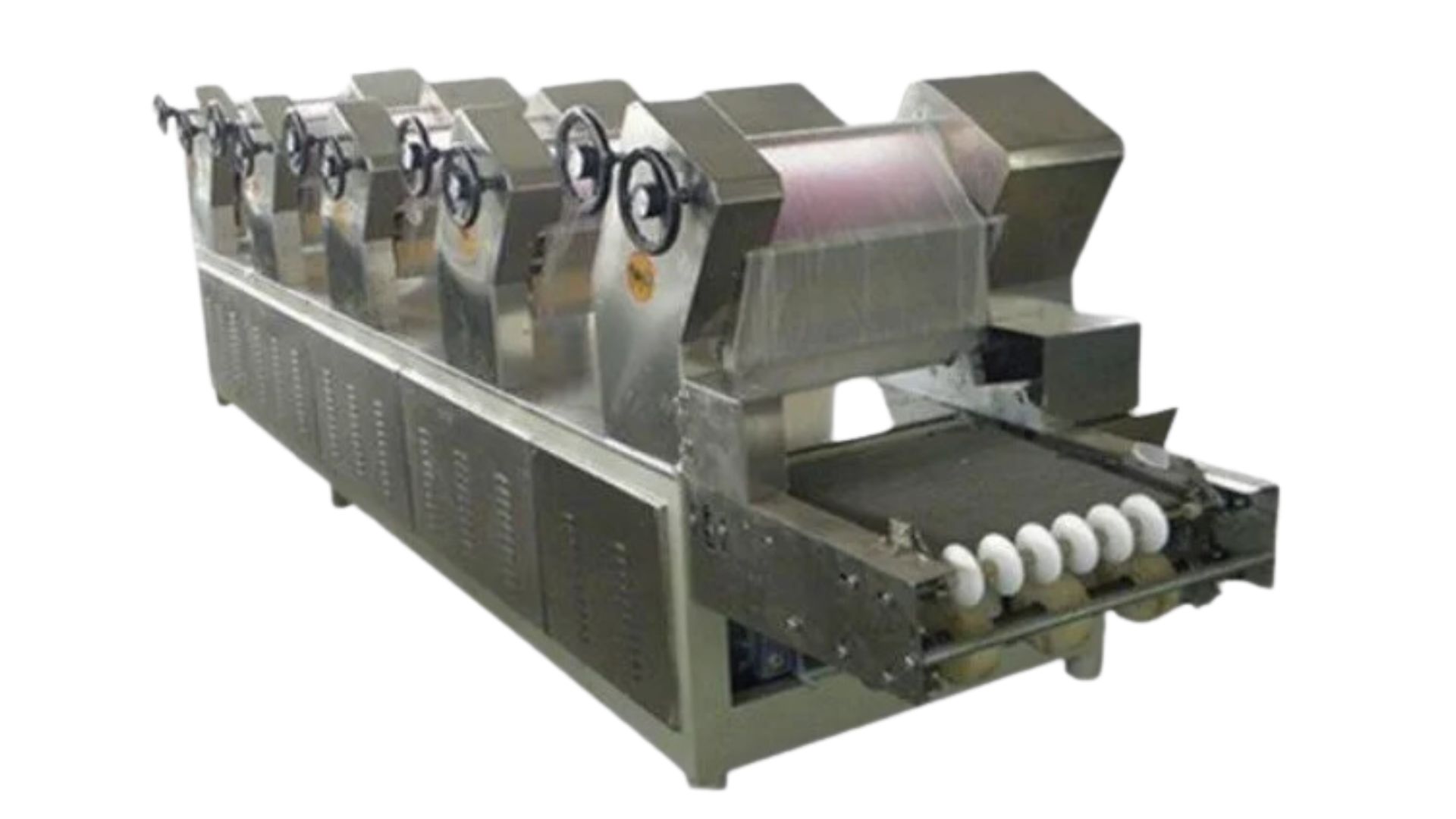

A continuous fryer is a specialized frying equipment used in food processing industries to continuously fry food products. It typically involves a conveyor system that continuously moves the food items through hot oil for frying.

How does a continuous fryer work?

A continuous fryer works by utilizing a conveyor belt or a similar system to continuously transport food products through a hot oil bath. The oil heats the food, causing it to cook or fry as it moves through the fryer. The conveyor speed and temperature are adjustable to control the frying process.

What types of food can be fried using a continuous fryer?

A continuous fryer can be used to fry a wide range of food products, including but not limited to french fries, potato chips, chicken nuggets, fish fillets, onion rings, and various other snack and processed food items.

What are the advantages of using a continuous fryer?

Continuous fryers offer several advantages, including consistent and uniform frying, high production capacity, efficiency in energy usage, precise temperature control, and the ability to integrate into automated production lines.

How is the oil replenished and maintained in a continuous fryer?

Continuous fryers typically have oil reservoirs or tanks where the frying oil is stored. The oil level is monitored, and replenishment is done as needed to maintain a consistent level. Additionally, oil filtration and cleaning systems are incorporated to remove debris and maintain the quality of the frying oil.

How is safety ensured in operating a continuous fryer?

Safety measures for operating a continuous fryer include proper training for operators, following safety protocols and guidelines, using protective equipment, ensuring proper ventilation to minimize fumes, and regularly inspecting and maintaining the fryer to prevent potential hazards.